Space inside the house is not something many of us have these days.

The following are some recommendations on how to transform a space in your apartment into an electronics hobby bench.

1) Tip#1: Extendable dining table.

Not a must, but a very nice to have.

2) Tip#2: Good lighting.

Change the bulbs on your ceiling so it is at the level you need. Be creative and build your own ceiling lamp to balance beauty with functionality. Or buy something that will illuminate your bench accordingly.

You can also add a desk lamp such as this:

3) Tip#3: Yoga mat, and even better: ESD mat.

This is a must. This not for relaxing (your hobby is actually for that).

It's to put over the table. It is non-conductive and it will not develop static electricity either.

It will accomplish the following:

- It clearly defines your working area. Easy to trim with scissors to the dimensions you like according to your own preference and arm length.

- It prevents small parts and screws from bouncing off the table and thus it will save you hours and hours of looking for them. Small screws always end up in the most unimaginable places when they bounce off the table, and you know it. Do the test and see how well this mat will absorb shock from falling parts.

- Provides comfort and warm and soft feeling for your arms.

- It will protect your dining table from scratches.

- It provides a cushioned area for your projects or to-be-repaired objects without scratching or damaging them (imagine disassembling an iphone on top of this versus the wooden table).

- It allows you to rapidly clean up your working area. Just lift it and empty thousands of cable insulator and bits of solder and sweat and blood directly on your trashcan! All in one single motion.

- It will eventually get stains and will melt when accidentally aiming your rework station or hot glue gun or soldering iron. You can always get a brand new one for a few dollars.

- And it's easy to fold or roll when not in use.

4) Tip#4: Get the basics

Depending on the nature of your hobby, your mileage may vary.

To me the essentials are:

- A soldering station.

Also solder wick and a good solder pump.

- A third hand and a Panavise.

- Tools. To your preference. Check for Collin's Lab: Electronics Tools

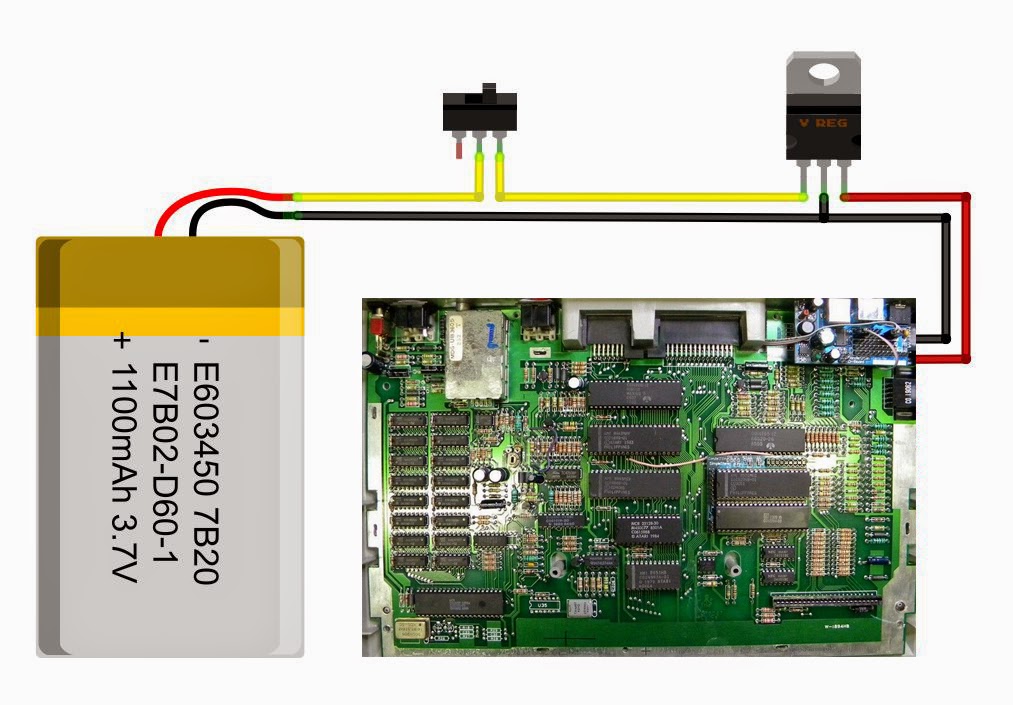

- Build an ATX power supply (for sense of accomplishment and endless use of 12V, 5V and 3.3V power with short protection and temp auto-shutdown). I like Jumper One ATX power supply. Add variable voltage capability with an LM317 Another one from JumperOne.

- A decent multi-meter. No need to go Fluke. Just nothing below $40 and you'll do fine.

- An oscilloscope. (You won't need it for general hobby use but eventually it will become helpful).

- A small table-top trashcan to toss your small bits of unwanted material.

- A digital microscope on the cheap: It's not easy to read chip labels or inspect soldering with your bare eyes. Get a manual focusing webcam and use it as a microscope (8 bucks).

- A rework station. For melting hot glue, shrinking heat-shrink tubing and yeah, to rework stuff.

- Isopropyl Alcohol, Q-tips for cleaning. I use it all the time.

- Small parts plastic organizer for putting in screws of the things you disassemble.

- A separate box for unfinished projects and less-used parts, which reminds me of..... step 5:

5) Tip #5: 5S your place.

Seriously. This is by far the most important piece of my advice. If you are not a 5S kind of person, become one. This is vital to be able to enable and disable your lab at will.

Don't know what I'm talking about? 5S describes how to organize a work space for efficiency and effectiveness by identifying and storing the items used, maintaining the area and items, and sustaining the new order. Read More

This means: Get toolboxes, drawers, stackable parts bins. Label and outline tool placement. A place for everything and everything in its place. Measure of success is to be able to put your lab together in 15 minutes and put it all out in 45 minutes (it takes longer to store it out because you end up with new stuff to find a place for, cleaning duties and you are generally more tired and slow). Improve until you succeed.

B) Bonus: Take it one step further

You are most likely skilled at DIY already, so grab your tools and build your own shelf, custom made to your own needs just like this wooden shelf for the Power Supply, scope and multi-meter: